COMING TOGETHER TO SUSTAIN OUR COMMUNITY

At Pride Mobility®, sustainability means more than our impact on the environment. It encompasses employees’ satisfaction, holding our suppliers to exceptional standards, creating sustainable production processes and our commitment to education.

This is not about chasing trends, though we recognize sustainability is definitely on-trend. It’s because we’re part of a community, which is part of a bigger world, and our decisions affect everyone.

Our sustainability model focuses on seven main efforts: Facility Sustainability, People First, Product Life Cycle Management, Safety, Supplier Commitment, Community Support and Education.

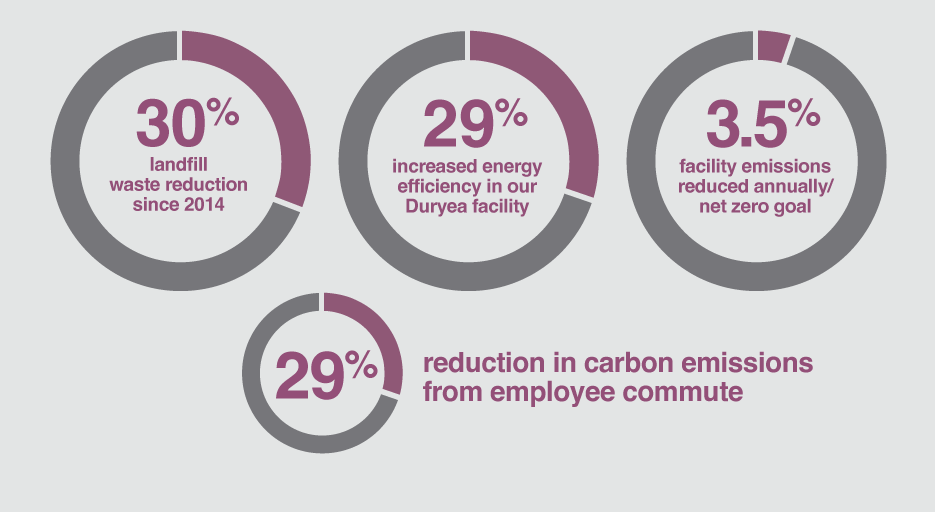

FACILITY SUSTAINABILITY

Through strategic consolidation and environmental irrigation plans, we’re reducing erosion damage and filtering pollutants from stormwater. We’re upgrading HVAC and lighting systems. We’re trying to maintain work-from-home policies which help our team commute less while remaining productive and efficient.

Less Waste.

Less Energy Consumption.

More efficiencies.

PEOPLE FIRST

When we let our people work from home during the pandemic, they did great work and many really liked the experience. So, we’re trying to continue a hybrid workplace model mixing in-office and remote work. Our goal is to provide more flexibility for employees while remaining efficient. We think treating employee happiness as a key part of our mission is why 40% of our team has been here 10 years or more. That’s higher than the national average.

Our employees include some of those whom we serve with our mobility products. Here's where we are and where we are going:

OUR BRANDS

OUR BRANDS